+86 137 0938 2367

+86 137 0938 2367

May. 05, 2023

In-Mold Labeling (IML) is revolutionizing the manufacturing industry with its cost-effectiveness, efficiency, and sustainability. IML solutions have been around for some time now, but they are gaining popularity due to their many benefits. In this article, we will explore IML solutions in detail, including their advantages, applications, and future prospects.

IML solutions have transformed the manufacturing industry by offering a range of benefits, from cost-effectiveness to sustainability. In this article, we will discuss how IML solutions work, their benefits, applications, and the future of IML in the manufacturing industry.

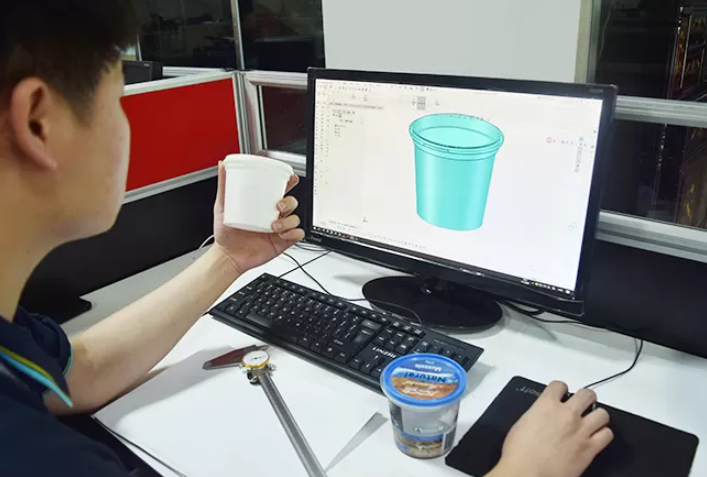

In-Mold Labeling (IML) is a manufacturing process that involves placing a pre-printed label inside a mold cavity before the plastic is injected into it. The label becomes an integral part of the product, creating a seamless, high-quality finish. IML is commonly used in the production of food packaging, cosmetics, and household items.

The IML process involves several steps, including:

ㆍPreparing the mold

ㆍPrinting the labels

ㆍPlacing the labels in the mold cavity

ㆍInjecting the plastic

ㆍCooling and ejecting the finished product

IML solutions can be fully automated, reducing the need for manual labor and increasing efficiency.

IML solutions offer several advantages over traditional manufacturing methods, including:

Cost-effectiveness

IML solutions reduce manufacturing costs by eliminating the need for separate labeling processes and reducing waste. The labels are also printed in high volumes, reducing the cost per label.

Efficiency

IML solutions can be fully automated, reducing the need for manual labor and increasing efficiency. The labels are also placed inside the mold cavity, reducing the chances of damage during transport or storage.

Sustainability

IML solutions are more sustainable than traditional labeling methods because they reduce waste and the need for additional packaging. The labels are also recyclable, reducing the environmental impact of the manufacturing process.

IML solutions have a wide range of applications, including:

Food packaging

IML is commonly used in the production of food packaging, including containers for dairy products, sauces, and soups.

Cosmetics

IML is used in the production of cosmetics packaging, including containers for creams, lotions, and shampoos.

Household items

IML is used in the production of household items, including containers for cleaning products, pet food, and storage containers.

IML solutions are expected to become more popular in the future, as manufacturers seek to reduce costs, increase efficiency, and improve sustainability. Advances in technology are also expected to improve the quality and flexibility of IML solutions, making them suitable for a wider range of applications.

IML solutions are revolutionizing the manufacturing industry by offering cost-effective, efficient, and sustainable solutions. The IML process involves placing a pre-printed label inside a mold cavity before the plastic is injected, creating a seamless, high-quality finish. IML solutions have a wide range of applications, including food packaging, cosmetics, and household items. The future of IML looks bright, with advances in technology expected to further improve its quality and flexibility.

What is IML?

IML stands for In-Mold Labeling, a manufacturing process that involves placing a pre-printed label inside a mold cavity before the plastic is injected into it.

What are the advantages of IML solutions?

IML solutions offer cost-effectiveness, efficiency, and sustainability benefits over traditional manufacturing methods. They reduce manufacturing costs, increase efficiency, and reduce waste.

What are the applications of IML?

IML solutions have a wide range of applications, including food packaging, cosmetics, and household items.

Is IML sustainable?

Yes, IML solutions are more sustainable than traditional labeling methods because they reduce waste and the need for additional packaging. The labels are also recyclable, reducing the environmental impact of the manufacturing process.

What is the future of IML?

The future of IML looks bright, with advances in technology expected to further improve its quality and flexibility, making it suitable for a wider range of applications.

Navigation

+86 596 6797 686

+86 137 0938 2367

Longchi Development Zone, Jiaomei Town, Taiwanese Investment Zone, Zhangzhou, Fujian, China