+86 137 0938 2367

+86 137 0938 2367

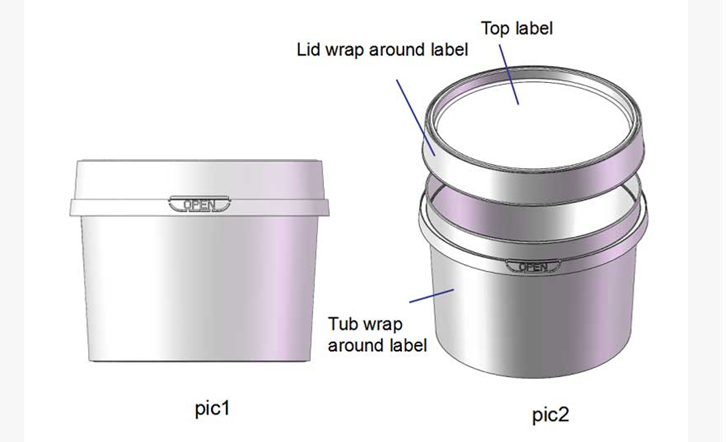

This is a successful project we develop and manufacture for Nestle Dreyers 800ml ice cream container. The original package is made into paper material which is easy to collapse during tranportation and selling. We helped Nestle solve technical problem, upgrade into rigid plastic lid and tub with IML injection molding process. The appearance of the lids shall be consistent with that of the original paper lids. It'd designed and molded out by 4 cavities, and two labels are used: the top label and the surrounding label. Due to the small height of the lid, the surrounding label of the lid is long and narrow (370x18mm), so the in mold labeling process has a very high process difficulty. We solve the process difficulties such as the standard label stock area, the labeling fixture, and the picking manipulator. This tub requires low temperature resistance of - 48 ℃. We have developed an intelligent production system with visual inspection, automatic stacking and automatic packaging to meet the test requirements and ensure food safety.

Navigation

+86 596 6797 686

+86 137 0938 2367

Longchi Development Zone, Jiaomei Town, Taiwanese Investment Zone, Zhangzhou, Fujian, China